When Bury Park made aeroplane propellers

Classification

Source

One of the most interesting branches of war work carried on at Luton was that of the manufacture of aeroplane propellers, at the establishment of Mr Edgar L. Barber, Bury Park Road.

A tour of his premises was extremely instructive, said The Luton News (January 30th, 1919). One saw the whole process, dating from the time the planks of walnut are carried into the shop in the rough state until they emerge again in the form of the finished article.

The industry, as is shown in the manner in which it has been developed, and the progress which has been made generally, speak well for the energy aptitude shown by the principal in meeting an urgent war demand and in making sound preparations to adapt conditions and plant to the altered circumstances of today.

In the course of a conversation, Mr Barber said that at the outbreak of the war he was engaged in his ordinary business as builder and shop-fitter, and was in the midst of several contracts. These having been completed, the staff was at once put on to war work. The shops were fitted up with necessary new plant for the construction of fuze trays for Messrs George Kent Ltd, Messrs Hans Renold, of Manchester, and many other well-known firms.

At this juncture the work was of a highly important character in connection with the manufacture of fuzes, for it formed the basis of the filling system in force in huge fuze-making shops. Upwards of half a million trays of various types were supplied to the firms mentioned. At the same time the firm turned out about 10,000 chairs for munition works and the Admiralty.

Following this, Mr Barber undertook aircraft work for Messrs Kent, who at that time were engaged in the construction of aircraft gun directors, and this brought the Bury Park Road shop within the schedule of protected occupations.

Subsequently it was suggested that the principal was well qualified, by reason of his pre-war experience in high-class woodwork and the suitable nature of his plant and shop, to take up the manufacture of aeroplane propellers.

The factory was inspected by the representative of a propeller firm of international reputation, and the principles of the art – for certainly it is an art – were enunciated in a practical manner.

The work was engaged in with great vigour and enterprise, and it is interesting to record that, almost without exception, the men so employed have been trained at the factory, and local labour almost exclusively was employed.

The work of propeller making demands the greatest care and patience, owing to its exacting character, and the fact that the margin of error permissible is so small as to be almost non-existent. The spindle upon which a propeller is tested for balancing purposes is so true and finely adjusted, running on Skefko ball bearings, that the addition of a piece of paper at the end of a ten-foot prop will disturb the balance.

The fineness of the work is thus obvious and carried the corollary that only highly skilled men are suitable for such employment. Mr Barber has cause for great satisfaction in the knowledge that the firm has won through to a very high place in the list of propeller makers. Further proof of this is available in the facts that props turned out at Luton have been used in the construction of the planes which have been doing the best of the work and the fighting – the Handley-Page fitted with Rolls-Royce engines; the Sopwith Scout, the Sopwith Camel (S.E.5 fitted with Hispano-Suiza engines), D.H.9 and finally D.H.10 (fitted with 400-hp engines).

As it was put to the writer, the firm was entrusted with the cream of the work in the direction of war-time activity.

The strain upon a propeller blade when the engine is developing 400 horsepower must obviously be enormous, and Mr Barber takes legitimate pride in the fact that 'rejects' from his establishment have been almost negligible.

There is, we gather, only one other propeller firm in Bedfordshire, and Luton has reason to be satisfied that a new phase of industry has now been established in the borough, providing skilled occupation for considerable numbers of residents.

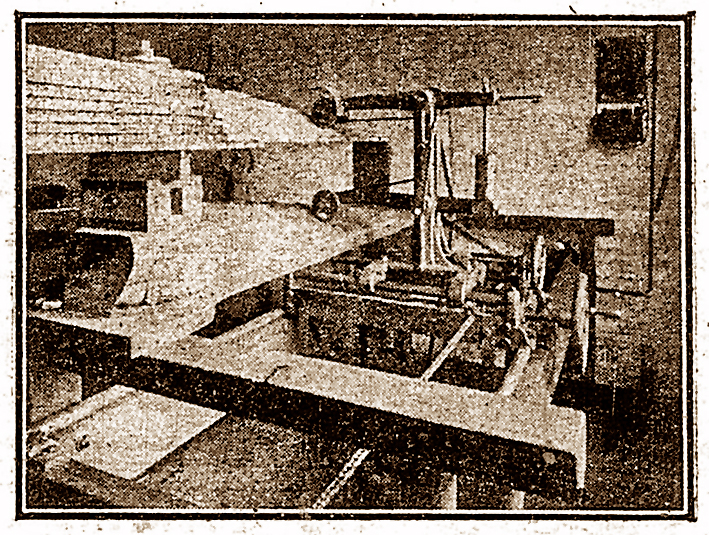

Nor has the firm finished at the production of the finished article. They have constructed a machine for the shaping of propellers. It is totally different in action from any other machine at present in use for similar work, and has given complete satisfaction in action – the best test of all.

Members of the Air Board have visited the factory to watch the machine under working conditions, and have paid his tributes to its efficiency.

The engineering work necessary in its construction was carried out by M. White & Co, of Luton, and it is known in the trade as the 'Barber and White patent propeller shaping machine' [pictured].

Like his fellow colleagues in other spheres of industry in the borough, Mr Barber is optimistic as to future prospects, and in view of the expected development of aircraft as a means of transport, national and international, it is reasonable to regard his hopefulness as justifiable.

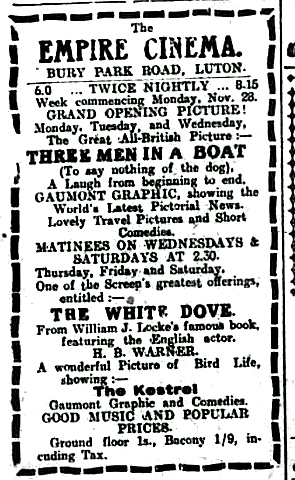

Aeroplane propeller production did not continue too long. By November 1921 Mr Barber had converted his building into the Empire Cinema, operated by Luton Cinemas Ltd.

Following a private showing before an invited audience the previous day, the cinema opened to the public on November 28th, 1921, described by The Luton Reporter newspaper the following day as “a West End cinema out of London”. It was planned by Castle Street architects Brown & Parrott and had seating for 440 people.

The Luton News of December 1st, 1921, wrote: “Everything is as perfect, and the equipment is as elaborate, as though carried out on the grand scale, with no prospect of being superseded by anything better for generations to come.

“Standing, as it does, in the curve of Bury Park Road, the building has been given an attractive exterior. The entrance leads to a no less attractive foyer, where features of the panelled walls area number of carved faces, representing among other subjects, a king, a queen, Charlie Chaplin, John Bull, Punch, comedy, tragedy etc.

“In the auditorium the most striking feature is the proscenium, which is unlike anything else in the town. The whole of the surroundings of the screen, which is placed at a considerable height from the floor, are decorated in Japanese design. This is striking enough in itself to call for comment, but is only when some concealed lamps are switched on that is found that completely surrounding the screen a charming design had been carried out in cathedral tinted glass.

“Building and equipment alike are designed to minimise the possibility of fire, and how effective the latest apparatus is may be gathered from the fact that when the licensing justices were viewing the place a film in one of the projectors was deliberately set on fire, but only about two inches actually burned.”

The report also said: “Incidentally, the padded ledge of the balcony front was the work of trainees at the Government Instructional Factory, Chaul End, and was done in a manner which earned them great credit.”

Manager of the cinema was Mr W. Austin, and projection was under the charge of Mr A. Smith, an operator with considerable London experience. The Empire was the first purely picture house in Luton to have an orchestra, consisting of piano, violin and cello, under the direction of Mr Reginald Clarke, a well known local violinist.

The slideshow below includes a contemporary photograph of the Empire Cinema from November 1921 and an advert for the opening week programme.

The Empire closed on October 15th, 1938, later to become first a Jewish synagogue and then an Islamic centre.

Author: Deejaya

Add comment